Summary

Membrane Bio-Reactor (MBR) is a new wastewater treatment system which combines membrane separation technology with biological treatment technology. It mainly consists of two parts: membrane module and bioreactor. A large number of microorganisms (activated sludge) are in full contact with the substrate (degradable organic matter in wastewater, etc.) in the membrane bioreactor, and metabolize through oxidation and decomposition to maintain their growth and reproduction, while degrading organic pollutants.

Fibracast membrane is used in HN-MBR. It can achieve better solid-liquid separation effect, realize direct reusing, and has higher membrane flux compared with domestic MBR membrane. So it can reduce the MBR footprint and cost. Low aeration can be achieved in operation, and this can reduce the frequency of chemical cleaning. Thus the daily operating costs and labor can be greatly reduced.

Features

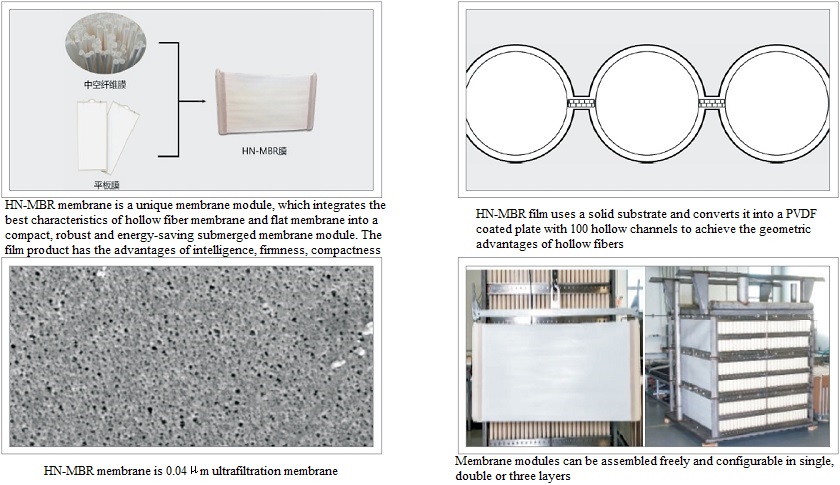

1) HN-MBR membrane is a unique membrane module, which integrates the best characteristics of hollow fiber membrane and flat membrane into a compact, robust and energy-saving submerged membrane module. The film product has the advantages of intelligence, firmness, compactness and easy replacement.

2) HN-MBR film uses a solid substrate and converts it into a PVDF coated plate with 100 hollow channels to achieve the geometric advantages of hollow fibers.

3) HN-MBR membrane is 0.04μm ultrafiltration membrane.

4)Membrane modules can be assembled freely and configurable in single, double or three layers.

Advantages

1) HN-MBR membrane technology can save secondary sedimentation tank and the footprint is small.

2) The flux of HN-MBR membrane can be as high as 25-35 L/m2.h, which is twice the flux of traditional hollow fiber membrane, thus reducing the membrane and footprint,indirectly reducing the construction cost.

3) In the bioreactor, the sludge concentration of HN-MBR membrane can reach up to 15 000 mg/L.

4) Chemical cleaning cycle is long, chemical cleaning demand is very low, 1-2 times a year.

5) The solid-liquid separation effect is good, the effluent suspended matter and turbidity are very low, and can be directly reused to realize the reuse of wastewater .

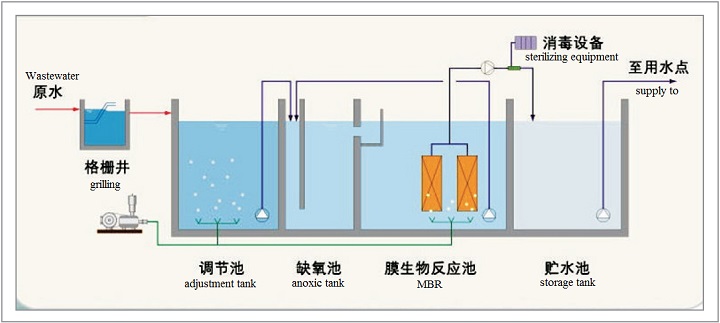

MBR P&ID

HN-MBR and conventional MBR

Item | Description | Plate membrane | Hollow fibre membrane | HN-MBR | HN-MBR VS Plate membrane | HN-MBR VS Hollow fibre membrane | The best |

Daily average flux L/(m2.h) | | 13.6-20.4 | 20.4-23.8 | 23.8-27.1 | Increase 100% at the most | Increase 33% at the most | HN-MBR |

Daily max flux L/(m2.h) | Able to treat high flux(such as blizzard or storm);impact to design the membrane flux | 30.5 | 37.5 | 47.5 | Increase 56% | Increase 27% | HN-MBR |

Assembly density (membrane surface per cubic meter of membrane tank | Footprint impacts the workshop cost | 90 | 250 | 480-500 | Increase 450% at the most | Increase 100% at the most | HN-MBR |

Aeration (per inch of membrane SCFM) | Impact the energy cost fighting block | 0.022 | 0.0085 | 0.006 | Reduce 275% | Reduce 40% | Plate membrane and HN-MBR |

Mixed liquid suspended solids | Solids density before membrane block | 14-15 | 10-12 | 14-15 | Same | Increase 50% | Plate membrane |

Acid washing | Additional washing to reach the max ability | None or little | 3-4 times per year | Twice per year | | A half | HN-MBR |

Disadvantages | | Easy stratification at welding | accumulation of mud; Easy to wear and tear | No welding and Oriental collecting pipe | No plate membrane disadvantages | No hollow fibre membrane disadvantages | HN-MBR |

Alternative | | Only plate membrane | Plate membrane Hollow fibre membrane | Plate membrane Hollow fibre membrane | Can not be replaced by plate membrane. HN-MBR efficiency is high and the footprint is low | Can not be replaced by hollow fibre membrane. HN-MBR efficiency is high and the footprint is low | HN-MBR |